Batch Production

Dynamic optimization of bioprocesses: efficient and robust numerical strategies 2003, Julio R. Banga, Eva Balsa-Cantro, Carmen G. Moles and Antonio A. Alonso

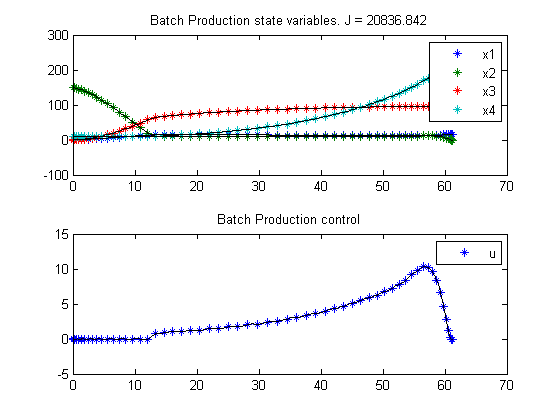

Case Study II: Optimal Control of a Fed-Batch Reactor for Ethanol Production

Contents

Problem description

This case study considers a fed-batch reactor for the production of ethanol, as studied by Chen and Hwang (1990a) and others (Bojkov & Luus 1996, Banga et al. 1997). The (free terminal time) optimal control problem is to maximize the yield of ethanol using the feed rate as the control variable. As in the previous case, this problem has been solved using CVP and gradient based methods, but convergence problems have been frequently reported, something which has been confirmed by our own experience. The mathematical statement of the free terminal time problem is:

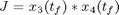

Find the feed flow rate u(t) and the final time tf over t in [t0; tf ] to maximize

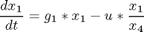

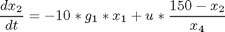

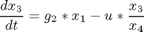

subject to:

where x1, x2 and x3 are the cell mass, substrate and product concentrations (g/L), and x4 is the volume (L). The initial conditions are:

![$$ x(t_0) = [1 \ 150 \ 0 \ 10]' $$](xbatchProduction_eq75568.png)

The constraints (upper and lower bounds) on the control variable (feed rate, L/h) are:

and there is an end-point constraint on the volume:

% Copyright (c) 2007-2008 by Tomlab Optimization Inc.

Problem setup

toms t toms tfs tf = 100*tfs; % initial guesses tfg = 60; x1g = 10; x2g = 150-150*t/tf; x3g = 70; x4g = 200*t/tf; ug = 3; n = [ 20 60 60 60]; e = [0.01 0.002 1e-4 0]; for i = 1:3

p = tomPhase('p', t, 0, tf, n(i)); setPhase(p); tomStates x1s x2s x3s x4s if e(i) tomStates u else tomControls u end %tomControls g1 g2 % Create scaled states, to make the numeric solver work better. x1 = 10*x1s; x2 = 1*x2s; x3 = 100*x3s; x4 = 100*x4s; % Initial guess % Note: The guess for tf must appear in the list before expression involving t. x0 = {tf == tfg icollocate({ x1 == x1g x2 == x2g x3 == x3g x4 == x4g }) collocate({u==ug})}; % Box constraints cbox = { 0.1 <= tf <= 100 mcollocate({ 0 <= x1 0 <= x2 0 <= x3 1e-8 <= x4 % Avoid division by zero. }) 0 <= collocate(u) <= 12}; % Boundary constraints cbnd = {initial({ x1 == 1; x2 == 150 x3 == 0; x4 == 10}) final(0 <= x4 <= 200)}; % Various constants and expressions g1 = (0.408/(1+x3/16))*(x2/(x2+0.22)); g2 = (1/(1+x3/71.5))*(x2/(0.44+x2)); % ODEs and path constraints ceq = collocate({ dot(x1) == g1*x1 - u*x1/x4 dot(x2) == -10*g1*x1 + u*(150-x2)/x4 dot(x3) == g2*x1 - u*x3/x4 dot(x4) == u}); % Objective J = final(x3*x4); if e(i) % Add cost on oscillating u. objective = -J/4900 + e(i)*integrate(dot(u)^2); else objective = -J/4900; end

Solve the problem

options = struct;

options.name = 'Batch Production';

solution = ezsolve(objective, {cbox, cbnd, ceq}, x0, options);

Problem type appears to be: con

===== * * * =================================================================== * * *

TOMLAB - Tomlab Optimization Inc. Development license 999001. Valid to 2010-02-05

=====================================================================================

Problem: --- 1: Batch Production f_k -4.151115744681614000

sum(|constr|) 0.259618778556077960

f(x_k) + sum(|constr|) -3.891496966125536100

f(x_0) 1.259999999999963600

Solver: snopt. EXIT=1. INFORM=32.

SNOPT 7.2-5 NLP code

Major iteration limit reached

FuncEv 4890 GradEv 4888 ConstrEv 4888 ConJacEv 4888 Iter 1000 MinorIter 4377

CPU time: 21.343750 sec. Elapsed time: 21.703000 sec.

Problem type appears to be: con

===== * * * =================================================================== * * *

TOMLAB - Tomlab Optimization Inc. Development license 999001. Valid to 2010-02-05

=====================================================================================

Problem: --- 1: Batch Production f_k -4.222925110913788400

sum(|constr|) 0.000001041586989401

f(x_k) + sum(|constr|) -4.222924069326799300

f(x_0) -1.852183384354953300

Solver: snopt. EXIT=0. INFORM=1.

SNOPT 7.2-5 NLP code

Optimality conditions satisfied

FuncEv 597 GradEv 595 ConstrEv 595 ConJacEv 595 Iter 547 MinorIter 1080

CPU time: 20.078125 sec. Elapsed time: 20.484000 sec.

Problem type appears to be: con

===== * * * =================================================================== * * *

TOMLAB - Tomlab Optimization Inc. Development license 999001. Valid to 2010-02-05

=====================================================================================

Problem: --- 1: Batch Production f_k -4.248461991804581400

sum(|constr|) 0.000004064043825988

f(x_k) + sum(|constr|) -4.248457927760755500

f(x_0) -4.126187506167310600

Solver: snopt. EXIT=0. INFORM=1.

SNOPT 7.2-5 NLP code

Optimality conditions satisfied

FuncEv 333 GradEv 331 ConstrEv 331 ConJacEv 331 Iter 159 MinorIter 629

CPU time: 6.921875 sec. Elapsed time: 7.062000 sec.

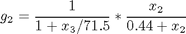

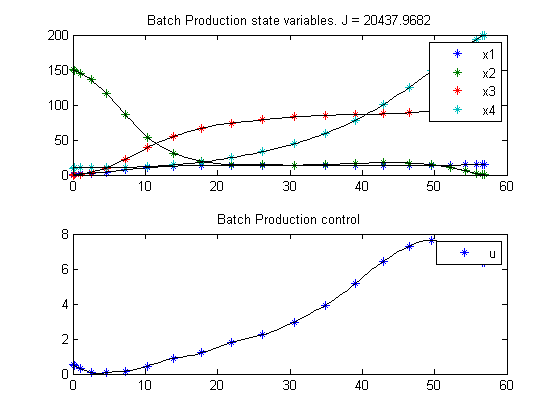

Plot result

subplot(2,1,1)

ezplot([x1 x2 x3 x4]);

legend('x1','x2','x3','x4');

title(['Batch Production state variables. J = ' num2str(subs(J,solution))]);

subplot(2,1,2)

ezplot(u);

legend('u');

title('Batch Production control');

drawnow

% Copy inital guess for next iteration

tfg = subs(tf,solution);

x1g = subs(x1,solution);

x2g = subs(x2,solution);

x3g = subs(x3,solution);

x4g = subs(x4,solution);

end