Denbigh's System of Reactions

Dynamic Optimization of Batch Reactors Using Adaptive Stochastic Algorithms 1997, Eugenio F. Carrasco, Julio R. Banga

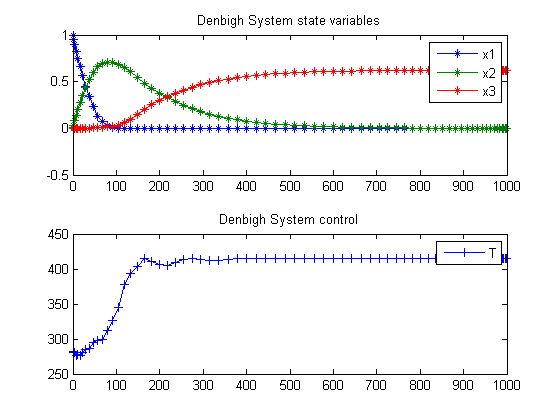

Case Study I: Denbigh's System of Reactions

Contents

Problem description

This optimal control problem is based on the system of chemical reactions initially considered by Denbigh (1958), which was also studied by Aris (1960) and more recently by Luus (1994):

A + B -> X

A + X -> P

X -> Y

X -> Q

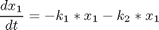

where X is an intermediate, Y is the desired product, and P and Q are waste products. This system is described by the following differential equations:

where x1 = [A][B], x2 = [X] and x3 = [Y]. The initial condition is

![$$ x(t_0) = [1 \ 0 \ 0]' $$](xdenbighSystem_eq76285.png)

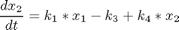

The rate constants are given by

where the values of ki0 and Ei are given by Luus (1994).

The optimal control problem is to find T(t) (the temperature of the reactor as a function of time) so that the yield of Y is maximized at the end of the given batch time tf. Therefore, the performance index to be maximized is

where the batch time tf is specified as 1000 s. The constraints on the control variable (reactor temperature) are

% Copyright (c) 2007-2008 by Tomlab Optimization Inc.

Problem setup

toms t

Solve the problem, using a successively larger number collocation points

for n=[25 70]

p = tomPhase('p', t, 0, 1000, n); setPhase(p); tomStates x1 x2 x3 tomControls T % Initial guess if n==25 x0 = {icollocate({ x1 == 1-t/1000; x2 == 0.15 x3 == 0.66*t/1000 }) collocate(T==273*(t<100)+415*(t>=100))}; else x0 = {icollocate({ x1 == x1_init x2 == x2_init x3 == x3_init }) collocate(T==T_init)}; end % Box constraints cbox = { 0 <= icollocate(x1) <= 1 0 <= icollocate(x2) <= 1 0 <= icollocate(x3) <= 1 273 <= collocate(T) <= 415}; % Boundary constraints cbnd = initial({x1 == 1; x2 == 0 x3 == 0}); % Various constants and expressions ki0 = [1e3; 1e7; 10; 1e-3]; Ei = [3000; 6000; 3000; 0]; ki4 = ki0(4)*exp(-Ei(4)./T); ki3 = ki0(3)*exp(-Ei(3)./T); ki2 = ki0(2)*exp(-Ei(2)./T); ki1 = ki0(1)*exp(-Ei(1)./T); % ODEs and path constraints ceq = collocate({ dot(x1) == -ki1.*x1-ki2.*x1 dot(x2) == ki1.*x1-(ki3+ki4).*x2 dot(x3) == ki3.*x2}); % Objective objective = -final(x3);

Solve the problem

options = struct;

options.name = 'Denbigh System';

solution = ezsolve(objective, {cbox, cbnd, ceq}, x0, options);

x1_init = subs(x1,solution);

x2_init = subs(x2,solution);

x3_init = subs(x3,solution);

T_init = subs(T,solution);

Problem type appears to be: lpcon

===== * * * =================================================================== * * *

TOMLAB - Tomlab Optimization Inc. Development license 999001. Valid to 2010-02-05

=====================================================================================

Problem: --- 1: Denbigh System f_k -0.632418776163711120

sum(|constr|) 0.000024152175629419

f(x_k) + sum(|constr|) -0.632394623988081660

f(x_0) -0.659999999999999250

Solver: snopt. EXIT=0. INFORM=1.

SNOPT 7.2-5 NLP code

Optimality conditions satisfied

FuncEv 1 ConstrEv 26 ConJacEv 26 Iter 19 MinorIter 1057

CPU time: 0.171875 sec. Elapsed time: 0.172000 sec.

Problem type appears to be: lpcon

===== * * * =================================================================== * * *

TOMLAB - Tomlab Optimization Inc. Development license 999001. Valid to 2010-02-05

=====================================================================================

Problem: --- 1: Denbigh System f_k -0.621639303673750640

sum(|constr|) 0.000000206291432199

f(x_k) + sum(|constr|) -0.621639097382318480

f(x_0) -0.632419741360300770

Solver: snopt. EXIT=0. INFORM=1.

SNOPT 7.2-5 NLP code

Optimality conditions satisfied

FuncEv 1 ConstrEv 10 ConJacEv 10 Iter 9 MinorIter 265

CPU time: 0.359375 sec. Elapsed time: 0.360000 sec.

end

t = collocate(subs(t,solution));

x1 = collocate(x1_init);

x2 = collocate(x2_init);

x3 = collocate(x3_init);

T = collocate(T_init);

Plot result

subplot(2,1,1) plot(t,x1,'*-',t,x2,'*-',t,x3,'*-'); legend('x1','x2','x3'); title('Denbigh System state variables'); subplot(2,1,2) plot(t,T,'+-'); legend('T'); title('Denbigh System control');